WDS Group leads the way to sustainability

Hospitality's continuing appetite for increased sustainability proves to be satisfying for our successful Collection Network partnership with WDS Group. We are also impressed by WDS Group's determined effort to make a significant environmental difference.

The beverage industry is stepping up its efforts to be more sustainable, and it's proactive businesses like WDS Group who are taking a hands-on approach to help businesses reduce their carbon footprint. Established in 2009, the Bury-based, family-run team at WDS Group have long recognised the importance of sustainability — they are a zero-landfill business that recycles all their trade waste, such as polythene and cardboard. Alongside an established wholesale and distribution network, their sustainability role involves collecting empty KeyKegs from pubs, bars, cafés and restaurants across Greater Manchester, Northern England and North Wales.

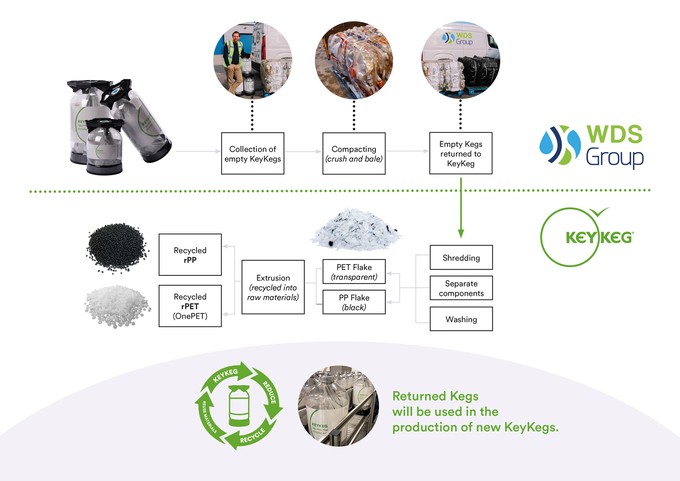

Hospitality professionals from Lancaster to York, Sheffield to Stoke, and everywhere in between, can help protect the environment by returning all their empty KeyKegs through WDS Group. KeyKeg is sustainable and designed for circularity — it is more than just recyclable. Empty Kegs can be recycled into the actual high-quality raw materials used in the production of new Kegs. As more empty Kegs are collected, the amount of recycled material in each new KeyKeg will steadily increase, conserving precious natural resources.

KeyKeg also reduces waste and limits the use of water, chemicals and fuel associated with traditional Kegs.

WDS Group joined the KeyKeg Collection Network in early 2019 and has already collected 55 tons of empty KeyKegs for recycling that may otherwise have ended up as landfill — a significant milestone.

Sam Evans, Sales Director, WDS Group: "The best thing about our partnership with OneCircle is that all empty KeyKegs we collect from pubs, bars and restaurants go back into the system and don't end up as landfill. We're glad to be part of the recycling process that helps turn empty Kegs into the materials used to make new Kegs. At WDS Group we want to continue collecting and recycling as many empty KeyKegs as we can across the North to create a greater positive environmental impact for the region."

WDS Group reduces the number of unnecessary journeys and minimises the carbon footprint by collecting empty Kegs as they travel around delivering some of the World's best beers, ciders and wines, as well as other hospitality supplies.

- The team crush the empty Kegs at their Bury warehouse and bundle them into 200-Keg bales for storage until we collect them.

- The different plastics in the empty Kegs we collect from WDS Group are shredded, separated and sorted on an automatic recycling line.

- The recovered mono-materials — PP, PE and PET — are further processed to produce the raw materials used for new KeyKeg parts.

- This ensures we reuse as much recycled material as possible.

- The remaining material is recycled for different uses.

We applaud the WDS Group team, and we support their aim to collect more empty KeyKegs for recycling. As more hospitality professionals return their empty KeyKegs for recycling, the amount of recycled material we use in every new KeyKeg will increase. And the industry will become more sustainable, thanks to the efforts of Collection Network partners like WDS Group.

WDS Group have produced a video about their KeyKeg collection.