KeyKeg | Circular, sustainable Kegs

We aim to leave the world a better place. Protect resources with circular-by-design, sustainable Kegs for beverages. When plastic is managed responsibly it contributes to climate and environmental objectives. Several scientific studies conclude that sustainable, circular plastics produce fewer CO2 emissions, protect natural resources, lower energy consumption and reduce waste. KeyKeg: reuse materials in a circular economy.

From KeyKeg recycling to a circular economy

KeyKeg is designed for circularity. Raw materials from empty KeyKegs are reusable for new plastic Kegs. We want to go beyond traditional recyclable Kegs to a circular economy in which we collect empty Kegs and recover the materials for producing new KeyKegs. Our sustainable Kegs are two-way and single use. It travels one way as a product to customers and returns to us as circular materials for KeyKeg reuse. Circularity avoids both downgrading material quality and downcycling material to produce lower-value products.

Key facts about KeyKegs

- A designed-for-circularity beverage-packaging solution

- Lightweight 10, 20 and 30 litre sizes are better for the environment

- Bag-in-Keg Technology allows fresh-beer dispense without C02

- Strong and safe Double-Wall Technology protection is sustainable

- Stable, stackable and easy to handle for logistics and staff safety

- Custom-branding promotes your preference for sustainable solutions

KeyKeg environmental responsibility

We do not want to see KeyKegs incinerated or used as landfill, so our goals include collecting all empty KeyKegs for recycling, for processing and reuse as materials in the production of new Kegs. Our sustainable Kegs are compliant with ISO 18604 because we care about the planet. Furthermore, we use green energy and all our plastic waste from Keg production is reusable for plastic Kegs.

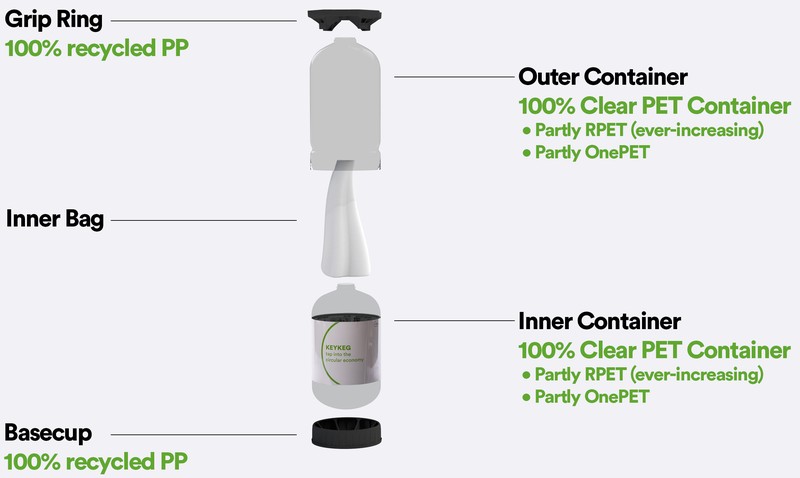

Sustainable OnePET increases circularity

We continue to innovate for progress, supporting our commitment to sustainability. For example, we do more than KeyKeg recycling, we recover the materials from empty KeyKegs to help us compose OnePET, a blend of mostly recycled polyethylene terephthalate (PET). OnePET consists of circular material from recyclable Kegs, mainstream recycled PET and just 15% of virgin PET. The more empty, sustainable Kegs we collect through our growing Return Network, the more OnePET we produce for KeyKeg reuse to increase our circularity.

Global Return Network for empty Kegs

We have proven that circularity is achievable in the industrial beverage-packaging market. To further our ambitious goals for sustainability, we are assembling a worldwide Return Network of partners to gather and process empty KeyKegs for reuse as materials in the production of new sustainable Kegs.

Our Return Network enables sustainable KeyKeg recycling initiatives that complement existing local waste-management streams. Connect with us for more information about sustainability and our Return Network. We also actively seek new partners to join our community, to collect and / or be a drop-off point for empty KeyKegs in their areas.

All there is to know about our return community

Read more about the KeyKeg Return Network and find a list of partners in the EU who will collect or take your sustainable Kegs, once empty.

What the numbers say about sustainable Kegs

ISO 18604 recyclability

86 Recyclable

KeyKeg is compliant with ISO 18604, the international standard for packaging-material recycling and the environment. While 86% of every empty KeyKeg is suitable for recycling, KeyKegs are designed to be circular rather than recyclable Kegs.

Designed for circularity

50 Circular material

Recycled polyethylene tetraphyte (rPET) must be ‘food grade’ quality for KeyKeg’s transparent walls, but circular-quality rPET is not always possible. Therefore, the amount of rPET we use fluctuates, but on average there is about 50% circular material in each new KeyKeg.

We can recycle 86% of every empty Keg to recover the high-quality circular materials used in new KeyKegs. The more empty KeyKegs we collect, the more circularity increases in each new Keg.

A growing Return Network collects empty Kegs for us to achieve our circularity goal, helping us reprocess the high-quality raw material that is reusable for new plastic Kegs.

Fully recyclable components

100 Recycled materials

The KeyKeg grip ring and basecup are made entirely of recycled polypropylene (rPP). These are the first KeyKeg components that are both 100% circular and made using 100% circular material.

Less transport cost

35 Higher load factor

65 Estimated cost saving

Due to their light weight, it is possible to transport 35% more beverage per truckload using our sustainable Kegs instead of using steel Kegs. More beverage in each load means fewer shipments, or a transport-cost saving of up to 65%.

Less glass waste

27 Bottles of wine in one 20 litre KeyKeg

5 Total weight of freight

One 20 litre KeyKeg replaces 27 bottles of wine. More wine can be transported per pallet and per container with our lightweight Kegs.

Environmental focus

25 Million tonnes of plastic

Each year, 25 million tonnes of plastic is produced in Europe, of which only 30% is recycled. 39% is incinerated and 31% is used for landfill (EU, 2018). Our KeyKeg reuse goal sees all empty KeyKegs used as circular materials for new Kegs instead of letting them be incinerated or used as landfill.

Reduce, recycle, reuse materials with KeyKeg

KeyKeg is designed for circularity. Discover how we go beyond traditional KeyKeg recycling and see an overview of our sustainability data.

Transporting lightweight, sustainable Kegs cuts CO2 emissions

Use less fuel and produce fewer CO2 emissions by distributing your beverages in lightweight Kegs. This reduces the amount of transport weight. KeyKeg represents around 5% of the total transport weight, meaning it is possible to transport 35% more beverage in each truckload when using our Kegs instead of steel. More beverage in each load means either fewer shipments or a transport-cost saving of up to 65%.

Waste less hot water and use fewer chemicals

Conserve precious natural resources and prevent any negative environmental impact by using sustainable Kegs. Empty KeyKegs, which could be recycled to recover the circular materials used to produce new KeyKegs, do not undergo the same intense cleaning routines as empty steel refillable beer Kegs. It is estimated that cleaning a returned steel Keg with harsh cleaning chemicals uses 8-20 L of hot water.

Sustainable KeyKegs

Frequently asked questions

What is the difference between recycling and circularity?

Recycling in a general sense means putting materials back into the raw-materials chain after use, which in most cases involves downcycling: the recycled material has become lower quality and is used to produce lower-value products. Downcycling is, more or less, a delayed form of waste.

The highest achievable level of recycling is circularity. Complete circular-material reuse with no downcycling is our ultimate goal for KeyKeg recycling. Rather than being recyclable Kegs, KeyKeg is actually designed for circularity, which means that when a KeyKeg is empty it can be used to produce new KeyKegs, with no loss of quality. In other words, circular-by-design KeyKegs are reusable plastic Kegs that are continually reused as their own raw materials.

What is ‘thermal recycling’?

‘Thermal recycling’ is often thought of as recycling, but it is actually the burning of waste. Modern waste-management plants incinerate waste to generate electricity, suggesting that waste materials continue to serve a purpose after use.

Why do we reject ‘thermal recycling’ as a sustainability claim?

We are as interested in our CO2 footprint as we are in our circularity. Plastic is a petroleum-based product, so burning plastic means burning fossil resources too. We therefore dismiss plastic combustion as a sustainability claim. This is reflected in our sustainable Kegs, which are ISO 18604 compliant; plastic incineration should be disregarded according to the ISO.

Why has KeyKeg moved from 100 % to 86 % circular?

We adhere to ISO 18604, an internationally recognised and verifiable ISO standard against which we measure the environmental performance of our sustainable Kegs. ISO 18604 rejects ‘thermal recycling’ as sustainable, and we agree. Till now, we stated KeyKegs were 100 % recyclable Kegs, but we want to be fully transparent, and we reject greenwashing. We acknowledge one small part of each KeyKeg is difficult to recycle and is subject to ‘thermal recycling’. KeyKeg is therefore 86 % circular rather than 100 %, but we are working to increase this percentage.

Where can I learn more about sustainable Kegs?

You can find more information on our sustainability page and across our website. We will also start to publish an annual sustainability report from 2022, in which we present updated figures and the process for measuring the sustainable performance of our circular Kegs. Sustainability is more than reversing climate change and protecting the environment, it is also supply chain management, human rights, labour rights and inclusiveness issues. All of which will be featured in our report.

What the KeyKeg Community says

“Beer packaging is crucial in keeping the beer fresh, to keep flavours as we have intended it. KeyKeg allows us to package our beer with minimal oxygen pick up, to prevent beer from oxidising.”

TÖNIS VAHER

Head of Marketing, Pohjala

What the KeyKeg Community says

“KeyKeg is the greatest solution for ensuring the taste and quality of our beer reaches customers as we intended. It’s the craft-beer industry standard and KeyKeg circularity also fits our philosophy for running a sustainable, honest and open business.”

KOEN OVEREEM

Owner and brewer, Rock City Brewing

What the KeyKeg Community says

“We look forward to introducing PB Packaging’s long-established customer network to KeyKeg’s innovative solution for the packaging of beverages. In addition, KeyKeg’s ability to maintain freshness we are particularly excited by the sustainability credentials of KeyKeg, which include the use of recycled materials and its recyclability.”

ANDREW ALLSOP

Executive Manager, PB Packaging

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

CATHY KERSSEMEIJER

Senior Account Manager Nordics & Eastern Europe

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

FIORELLA RAVEN

Account Manager Iberia and Latin America

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

KILIAN VAN WOERKOM

Account Manager Benelux and South Africa

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

NATALIE MAESTRI

Sales Manager UK & Ireland

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

SAMUEL GRACZYK

Account Manager USA

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

MICHAEL MACK

Account Manager USA and Canada

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

RAYMOND KENT

Account Manager Australia, Middle East & Asia

Tap into sustainability knowledge!

Ask your dedicated Account Manager about KeyKeg reuse of circular materials, why KeyKegs are more than just recyclable Kegs and how we move beyond KeyKeg recycling to a circular economy. Ask why our sustainable Kegs add value to your beverages.

GABRIEL FRIEDMAN

Account Manager Italy